3.00mm Stepped Point Cobalt Drill Bit for Stainless & Hardened Steel - 135° Tip, Round Shank

- SKU:

- GSCMM3.00

- Ships Today! (Order By 3pm EST M-F)

- GSCMM3.00

- Ships Today! (Order By 3pm EST M-F)

3.00mm Stepped Point Cobalt Drill Bit for Stainless & Hardened Steel - 135° Tip, Round Shank

- SKU:

- GSCMM3.00

- Brand

- Qualtech

- UPC:

- 887861330145

- MPN:

- GSCMM3.00

- Availability:

- Ships Today! (Order By 3pm EST M-F)

FREE Two-Day Shipping on orders over $100

Description

This stepped point cobalt drill bit is engineered to start faster and drill cleaner holes without the need for a pilot bit. The precision stepped point geometry delivers instant centering and reduced walking, while the premium cobalt construction provides longer life in stainless steel and hardened metals.

- Stepped Point Cobalt Drill Bits start easier, drill faster, increase lifespan and reduce heat compared to standard drill bits

- Premium cobalt alloy increases heat resistance and extends tool life in stainless and hardened steel

- 135° split point tip improves centering and drilling stability

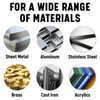

- Ideal for enlarging existing holes or creating new, clean holes in stainless steel, alloy steel, aluminum, brass, acrylic, and other metals

- Round shank for wide range of tool holding systems

- Suitable for stainless steel, hardened steel, alloy steel, tool steel, cast iron, aluminum, brass, acrylics and more

- Suggested Pack Quantity: 12

What It Is

This stepped point cobalt drill bit is a premium industrial cutting tool engineered for stainless steel and hardened metals. Featuring precision stepped point geometry and a 135° split angle, it is designed to start cleanly, minimize heat buildup, and extend tool life in demanding metal drilling applications.

What Makes It Different

Unlike standard drill bits, the stepped point geometry begins cutting immediately on contact. The design helps the bit self-center, significantly reducing walking and eliminating the need for a pilot hole in most applications. The 135° tip angle is optimized for stainless steel and other high-strength alloys, allowing smoother entry and improved stability throughout the cut.

Manufactured from premium cobalt alloy, this drill bit offers superior wear resistance and heat tolerance compared to standard high-speed steel (HSS) bits. The cobalt composition maintains edge sharpness longer, especially when drilling tough, abrasive materials.

Applications

Ideal for use in drill presses, CNC machines, and heavy-duty hand drills, this stepped point cobalt drill bit is built for precision metalworking environments including industrial fabrication, automotive repair, aerospace manufacturing, and general machining. Designed for:

- Stainless steel

- Hardened steel

- Alloy steel

- Tool steel

- Cast iron

- Aluminum and brass

- Acrylics

Frequently Asked Questions

What makes a stepped point drill bit better than a standard drill bit?

A stepped point begins cutting immediately and stays centered as it enters the material. This reduces walking, improves hole accuracy, and produces cleaner holes compared to standard 118° or split point drill bits.

Do stepped point drill bits require a pilot hole?

No. Stepped point drill bits are designed to self-center on contact, which reduces walking and eliminates the need for a pilot hole in most stainless steel and hardened metal applications.

What is a stepped point drill bit used for?

A stepped point drill bit is used for drilling stainless steel, hardened steel, and other tough metals where accuracy, reduced walking, and clean hole quality are important.

Is cobalt better than HSS for stainless steel?

Yes. Cobalt drill bits offer higher heat resistance and improved wear characteristics compared to standard high-speed steel (HSS), making them better suited for stainless steel and hard alloys.

What materials can a stepped point cobalt drill bit cut?

Stepped point cobalt drill bits are designed for stainless steel, hardened steel, alloy steel, tool steel, cast iron, aluminum, brass, and acrylic.

Can stepped point drill bits enlarge existing holes?

Yes. The stepped geometry allows the bit to enlarge existing holes or create new, smoother holes with improved stability and reduced chatter.

What does a 135° tip angle do?

A 135° tip angle improves centering and stability when drilling hard metals. It reduces walking and allows the bit to engage stainless steel more efficiently than a standard 118° tip.

Product Specs

Size: |

3.00mm |

Material: |

Cobalt |

Finish: |

Gold Oxide |

Flute Length: |

41.00mm |

Overall Length: |

61.00mm |

Shank Type: |

Round |

Style: |

Jobber |

Cutting Angle: |

135 |

Point Type: |

Stepped |

Number of Flutes: |

2 |

Cutting Direction: |

Right Hand |

Suggested Pack Quantity: |

12 |

Alternate Pack QTY SKU: |

GSCMM3.00P12 |